The material with staying power

The most valuable property of cemented carbide is that it offers a safer and more dependable solution than any other known material to one of the toughest problems which engineers have to contend with reliability.

Reliability is often a problem of wear. And wear resistance is the most outstanding feature of cemented carbide. If the material also has to withstand deformation, impact, heavy load, high pressure, corrosion and high temperature, cemented carbide is often the only material that can fulfil these requirements satisfactorily. It has long been a well-known fact that the use of cemented carbide

provides an optimal solution in the case of tools for metal cutting and rock drilling. Over the yeats cemented carbides have also proven their superiority in a great number of other tooling and engineering applications.

Looking at industrial equipment and consumer products in general, failures are often caused by the breakdown of a single component or structure. The solution may be to switch to a high-performance carbide part.

Experience shows that design solutions result from the close cooperation of engineers representing the application and carbide technologies. The best results are attained when these contacts have been established at an early stage of a development project, when it is still possible to adjust the design and take full advantage of the carbide.

The purpose of this document is to serve as a reference manual on the design and application of cemented carbide.

The data and graphs shown represent typical values from laboratory tests.

Recommendations regarding the selection of grades for specific applications are based on both laboratory tests and experience, and can be used only to indicate the fitness in other similar applications

The term "hard materials" refers to materials harder than the hardest steel. The hardest of these is diamond

followed by cubic boron nitride and ceramics. After these comes cemented carbide - currently the most important technical hard material which covers a wide range of hardness and toughness combinations

Cemented Carbide types

Cemented carbides are a range of composite materials which consist of hard carbide particles bonded together by a metallic binder. The proportion of carbide phase is generally between 70-97 % of the total weight of the composite and its grain size averages between 0.4 and 10µm

Tungsten carbide (WC), the hard phase, together with cobalt (Co), the binder phase, forms the basic cemented carbide structure from which other types of cemented carbide have been developed. In addition to the straight tungstencarbide - cobalt compositionscemented carbide may contain varying proportions of titanium carbide (TiC), tantalum carbide (TaC) and niobium carbide (NbC). These carbides are mutually soluble and can also dissolve a high proportion of tungsten carbide. Also, cemented carbides are produced which have the cobalt binder phase alloyed with, or completely replaced by, other metals such as iron (Fe), chromium (Cr), nickel (Ni), molybdenum (Mo), or alloys of these elements.

Thus, there are three individual phases which make up cementedcarbide. In metallurgical terms, the tungsten carbide phase (WC) is referred to as the a-phase (alpha), the binder phase (i.e. Co, Ni etc.) as the j3-phase (beta), and any other single or combination of carbide phases (TiC, Ta/NbC etc) as the '1phase (gamma).

Other than for metal-cutting applications, there is no internationally accepted classification of cemented carbides. However, the cemented carbide grades developed by Sandvik fall into four main groups as described on the next page.

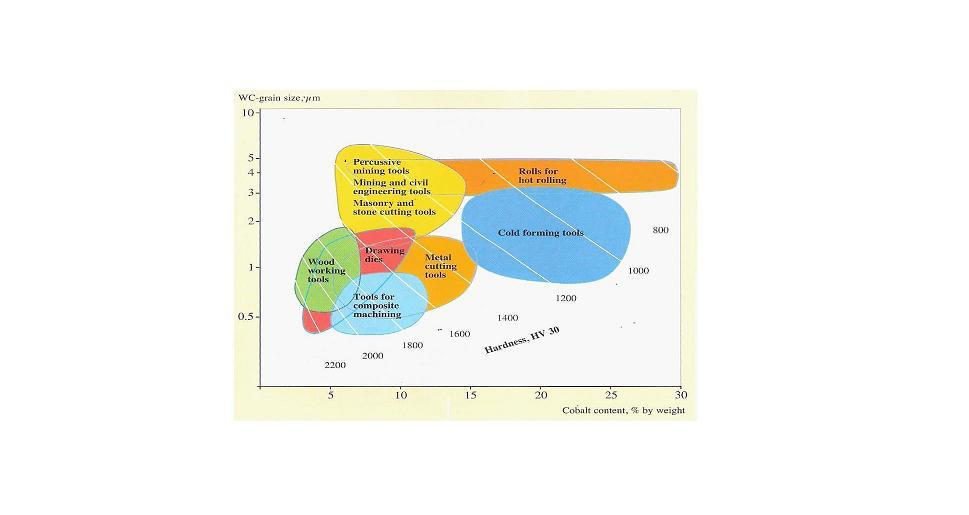

The application range of straight grade cemented carbide.

Front cover illustration:

Microstructure of extra coarse grained we-co cemented carbide after

electroLytic etching. Magnifica/ion: J 500x.

WC-Co grades

This group contains WC and Co only (i.e. two-phases) and a few trace elements. These grades are classified according to their cobalt content and WC grain size.

The grades with a binder content in the range 10-20 % by weight and WC-grain sizes between I and 5 JIm have high strength and toughness, combined with good wear resistance.

The grades with binder contents in the range 3-15 % and grain sizes below I JIm have high hardness and compressive strength, combined with exceptionally high wear resistance.

The Sandvik grade programme also includes WC-Co grades which utilise a range of ultra-fine WC grain sizes « 0.5 JIm). With such fine, uniform grain sizes, a unique combination of hardness, wear resistance and toughness can be achieved.

Corrosion resistant grades

This group contains cemented carbide grades in which the binder phase has been specifically designed to improve corrosion resistance above those grades which contain cobalt alone.

This is achieved by alloying the cobalt binder phase with elements such as nickel and chromium, or completely replacing it with a more corrosion resistant alloy.

Dual Property (DP) grades

This group contains grades which have had the distribution of their binder phase modified in such a way as to create a material with different properties in the surface zone compared with the bulk.

This entirely new concept, developed by Sandvik, enables components to be produced which contain distinct microstructural zones, each with a different binder content. Thus, each zone has different properties - hence the term "Dual Property".

More information on DP Carbide can be found on page 17.

Grades containing cubic carbides

This group consists of grades containing a significant proportion of v-phase, (Ti, Ta, Nb)C together with WC and Co, (i .e., three-phase materials) .

The main features of the 1'phase are good thermal stability, low grain growth, and resistance to oxidation.

These grades have been designed to provide a good balance of wear resistance and toughness in applications in which there is intimate contact with ferrous materials and in which a high temperature is generated. Typically, these conditions arise in metal cutting or high pressure sliding contact situations where welding and galling of the surfaces are encountered.

Grain size classification

grain size classification for all standard grades.

ultra fin Extra fine Fin Medium Medium Coarse Coarse Extra Coarse

Material properties

Wear resistance

The most important characteristic of cemented carbide is its wear resistance. This property, or more correctly, combination of properties, is related to surface phenomena.

When two surfaces slide against each other, material will be removed from both of them. At a low load, this loss of material will take place through the loss of single grains or parts of single grains. This process is generally referred to as attrition.

At higher load, the loss of material takes place by clusters of grains becoming detached. This process is known as abrasion.

Both these processes, leading to loss of surface material, contribute to wear. In practice, the material loss is often also affected by the local environment, particularly if corrosion or oxidation is encountered.

The nature of wear is very complex and the wear rate depends on many variables. General values for comparative purposes should be viewed critically. However, evaluations of wear resistance can be done in the laboratory under standardised conditions. Such evaluations indicate the ranking between the tested materials under these specified conditions only.

.jpg)

In a test based Oil ASTM 86/1-85, the test sompte is pressed against the periphery of a rotating disc, partly immersed in a slurry of alumina (AI20J) particles in water. The abrasive wear resistance is influenced by the cobalt content and the tungsten carbide grain size as shown in the diagrams.

.jpg)

.jpg)

Toughness

When components are exposed to external loads, static or dynamic, mechanical stresses occur within the material. The mechanical strength and deformability of the material are therefore important. In many cases, particularly when dealing with shock loading. both these properties must be considered simultaneously. This forms the background to the term "toughness" which can be defined as "the ability to resist fracture", i.e. a complete separation into at least two parts.

Toughness can be defined and determined in many ways. With the above definition, the integrated product of force and deformation to fracture, can be used as a toughness value.

A method commonly used for determining the toughness of cemented carbides is the Palmqvist method. In this case, the fracture toughness of the material is represented by its critical stress intensity factor K1c.

The results of toughness tests show that this property increases with increasing binder content, and with increased we grain size.

In comparison with other metallic materials, carbide is on the lower part of the toughness scale, approximately at the same level as hardened steel.

By definition, and confirmed by examining fractured surfaces, cemented carbide must be classified as a brittle material, as practically no plastic deformation precedes fracture. However, different cemented carbides show large differences in toughness behaviour. This is best explained by a close look at the microstructure. The types of fracture seen are cleavage fractures in carbide grains, grain boundary fractures between carbide grains and shear fractures in the binder. Generally, the amount of cleavage fractures increases with increased grain size and the amount of shear fractures with increased binder content. Expressed as fracture energy, the major contribution to toughness, is from the latter. i.e. the crack path through the binder.

Modern fracture mechanics provide a means of explaining toughness as it deals with the conditions for crack initiation and growth in nonhomogeneous materials under stress.

.jpg)

.jpg)

Wear resistance and toughness are two complex properties, both of which provide the ability to withstand the

destruction of a material. A high wear resistance is possible only if the demand for high toughness is reduced and vice versa. However, high wear resistance and high toughness can be achieved simultaneously, provided these properties can be re-distributed. There are two ways of doing this: DP carbide or coating with thin layers of wear resistant materials. There are numerous potential combinations and,consequently, only homogeneous, conventional

carbide will be dealt with below.

Hardness

Hardness is normally determined using the Vickers indentation method according to EN 23 878 (ISO 3878). This method allows a range of loads but HV30 is preferred. The force of a 30 kg weight, 294 N, is used to create a measurable indentation with minimal cracking at the comers. For the hardest grades the size of the impression and cracking contribute to reduced precision and accuracy.

Sometimes other methods are used such as Rockwell A (ISO 3738). The Rockwell method is similar to Vickers, but is based on the use of a diamond cone and the depth of the indendation is used as a measure of the hardness. There is no theoretical basis for conversion between the two. Instead actual determination must be used for comparisons.

Hardness increases with decreasing binder content and decreasing grain size. The hardness range extends roughly from that of tool steels, 700 HV30, up to 2200 HV30.

Hardness decreases with increasing temperature due to increasing plasticity.

.jpg)

The Vickers method is based on indenting a polished carbide surface with a diamond pyramid. The hardness is inversely proportional to the size of the impression.

Mechanical strength

All materials contain some amount of defects such as pores, inclusions and micro-cracks. These defects lead to a reduced material strength.

In the case of a ductile material (copper, mild steels, etc.) defect frequency and mean size are important factors, whereas in the case of a brittle material (e.g. hardened steels and carbide) the frequency above a certain size limits the strength. Consequently, this latter phenomenon makes the mechanical strength volume dependent as the probability of finding a large defect increases with increased material volume.

Weibull has related the volume dependence of critical defects within a material to the material strength. The conclusion of the Wei bull theory is that the relationship can be described using the formula: .jpg)

where.jpg) and

and .jpg) are the fracture stresses corresponding to the volumes V I and V" respectively, and m is a factor derived from the spread in fracture stress of the material.

are the fracture stresses corresponding to the volumes V I and V" respectively, and m is a factor derived from the spread in fracture stress of the material.

Modern high quality carbide has an m-value of about 9. High m-values correspond with small variations in fracture stress and a less volume-dependent material.

In practice the stress distribution is complex and the Weibull theory only provides a partial description. However, a calculation of the fracture probability of a certain carbide volume with a known stress distribution is possible.

A high quality carbide is normally regarded as an extremely defectfree material.

However, shaping processes, such as grinding and spark erosion, may lead to the introduction of large surface defects, thereby reducing the strength of the finished product.

The use of inferior quality carbide, in which defects already exist,

increases the risk of both early failure and variations in performance.

Transverse rupture strength

Transverse rupture strength (TRS) or bending strength testing is the simplest and most common way of determining the mechanical strength of cemented carbide. According to the standardised method EN 23 327 ([SO 3327), a specimen of a specified length with a chamfered, rectangular cross section is placed on two supports and loaded centrally until fracture occurs.

TRS is taken as the median of several observed values. TRS reaches a maximum at a cobalt content of about 15 % (by weight) and a medium to coarse we grain size.

The small portion of plastic deformation is generally disregarded as it is only noted in the toughest carbides.

The test pieces should be either as sintered or ground.

.jpg)

.jpg)

.jpg)

A careful grinding, conducted without any introduction of cracks or surface defects, will increase the TRS values compared to values obtained from assintered specimens.

The carbide rotary toolmaking sector in industry has adopted a modified TRS testing method more applicable to the geometry of solid carbide tooling and allowing a rapid testing procedure.

In this test a modification of the standard test specimen according to EN 23 327 eISO 3327) is used. This comprises a cylindrical specimen, 03.25 x 38 mrn. This modified test has been adopted as an industry standard and is now proposed to be included in the ISO-standard. By using this cylindrical test specimen, the edge effect of the rectangular standard specimen is avoided. As a result, the data gained from this test shows higher TRS values than with the rectangular test piece. Typically, the TRS values obtained from the cylindrical specimens exceed the level of the square specimens by about 20%. Thus, caution must be used when data are compared.

Transverse rupture strength decreases with increasing temperature. At prolonged load times and high temperatures, the cemented carbides will exhibit creep behaviour.

.jpg)

.jpg)

Tensile strength

Tensile strength testing of brittle materials is difficult. The accuracy of the test is extremely sensitive to sample preparation (the surface must be "perfect") and to superimposed loads from the fixtures, resulting in complex additional stresses.

However, by using the Wei bull theory, it is possible to derive the tensile strength from the TRS value. With m=9 the tensile strength is 56% of the TRS value.

Compressive strength

One of the most important properties of cemented carbides are their extremely high compressive strength under uniaxial loads. The stress mode with this type of load does not actually lead to "compressive fracture", but to a situation closer to a shear fracture. The shear stress at fracture of the compressed specimen is about half of the compressive stress which is much higher than the pure shear strength.

A suitable method of compressive strength determination is defined by EN 24 506 (ISO 4506). To obtain accurate values with cemented carbide, a modified specimen geometry must be used in order to overcome the edge and contact effects associated with a simple cylindrical test pIece. When the load is appl ied, there is first an elastic deformation, but prior to fracture there will also be a certain amount of plastic deformation. The stress/strain curve can be characterised in the normal fashion, with, the inclination from the origin (Young's modulus), one or more residual strain values and the fracture stress. The degree of plastic deformation decreases with increasing compressive strength.

The compressive strength increases with decreasing binder content and decreasing grain size. A carbide grade with a small we grain size and a low binder content has a typical compressive strength approaching 7000 Nzrnm-.

The compressive strength decreases with increasing temperature. The proportion of plastic deformation increases dramatically with temperature, leading to a barrel shaped specimen before fracture, thereby making results uncertain.

Shear strength

Pure shear tests are difficult to carry out. Studies of fractured pieces, however, indicate that the shear strength is at the same level, or slightly higher, than that of the tensiIe strength.

.jpg)

.jpg)

Fatigue strength

The fatigue strength of cemented carbide under pulsating compression loading is normally 65-85% of the static compressive strength at 2x I 06 cycles. No definite fatigue strength limit, which corresponds to an infinite life, has been found as in the case of steel and other metals.

The fatigue strength increases with decreasing WC grain size and decreasing binder content

Young's modulus, shear modulus and Poisson's ratio

.jpg)

Young's modulus, shear modulus and Poisson's ratio

Cemented carbide is a very rigid material. Its modulus of elasticity or Young's modulus (E) is 2-3 times higher than that of steel and increases linearly with decreasing binder content. Additions of v-phase reduce Young's modulus. Accurate measurements are hard to accomplish by means of stress/strain curves alone. Thus, resonance measurements of transverse or longitudinal waves are used to provide more reliable results. Young's modulus is determined according to EN 23 312 (ISO 3312).

The shear modulus (G) is best determined in a similar way using torsion waves. Values for cemented carbide lie between 180 and 270 kN/mm'.

With E- and G-values, Poisson's ratio (v) can be calculated according to the formula: .jpg)

.jpg)

Density

Density is determined according to the standard EN 23 369 (ISO 3369). The wide variation in the density of the constituents of cemented carbide (i.e. WC=15.7 g/cm", Co=8.9 g/cm>, TaC 13.2 g/crn" and TiC=4.9 g/cm') result in large variations in the density of cemented carbides in line with their composition.

Typically, the density of the cemented carbides can be 50-100% greater than that of the steel. This is an important consideration when weight is a major factor in component design.

.jpg)

Thermal properties

Linear expansion coefficient

As tungsten carbide has a very low linear expansion coefficient, WCCo cemented carbides have values of approximately half that of fenitic and martensitic steels while the ratio to austenitic steels is about 1:3.

If titanium carbide is included, the values will be slightly higher than for straight WC-Co cemented carbides

.jpg)

Thermal conductivity

The thermal conductivity of WCCo cemented carbides is approximately twice that of unalloyed steels and one third of that of copper. The tungsten carbide grain size has a minor effect but the presence of '1phase decreases the thermal conductivity considerably.

.jpg)

Specific heat capacity

At room temperature, the specific heat capacity for straight WC-Co grades is about 150-350 J/(kgo'C), which is nearly half the value of unalloyed steels.

Electrical and magnetic properties

Resistivity

WC-Co cemented carbides have low resistivity and a typical value is 20 fiDem. Cemented carbides with v-phase have a higher resistivity.

Conductivity

As a consequence of the low resistivity, the WC-Co cemented carbides are good conductors, having a value around 10% of the copper standard Alloying with 'I-phase forming car bides, e.g. titanium carbide, reduces this value considerably. Due to the preseuce of cobalt (and nickel) in the binder phase, cemented carbides show ferromagnetic properties at room temperature.

Curie temperature

The transition of the cobalt binder phase from the ferromagnetic to the paramagnetic state occurs in a temperature range between approximately 950 to 1,050 'C depending on the alloy composition.

Permeability

Although WC-Co cemented carbides contain a ferromagnetic binder phase, they usually have low magnetic permeability. It increases with the cobalt content and the typical range of values is 2 to about 12 when the vacuum value is equal to 1.

Corrosion resistance

Corrosion of cemented carbide leads generally to a surface depletion of the binder phase and, thus, the surface region will remain only as a carbide skeleton. The bonds between adjacent carbide grains are rather weak and the deterioration rate will increase accordingly. At low binder phase contents, the carbide skeleton is more developed and, accordingly, such grades exhibit a somewhat higher combined wear and corrosion resistance than corresponding grades with higher binder phase contents.

However, in practice, this effect is insufficient to offer a significant life improvement. The limited corrosion resistance of straight WC-Co grades often makes them unsuitable in applications where the corrosive conditions are severe. For these applications Sandvik has developed a series of highly corrosion resistant grades.

As shown in the diagram, straight WC-Co grades are resistant down to pH 7. This is also valid for WC-Co grades containing cubic carbides like TiC, TaC and NbC. The highest corrosion resistance is obtained for certain alloyed TiC-Ni based grades, which are resistant down to about pH 1, but compared to the straight WC-Co grades they are brittle and have inferior thermal conductivity. They also have the disadvantages of being difficult to grind and braze and, therefore, they are only used in specific applications with high demands on corrosion and wear resistance but in which mechanical strength and thermal shock resistance are less important.

Tn most corrosion-wear situations, the better choice is specially alloyed WC-Ni grades, which are resistant down to pH 2-3. Even in certain solutions with pH values less than 2 they have proved to be resistant to corrosion. As they have WC as the hard principle, and Ni and Co are similar metals in most respeets, their mechanical and thermal properties are comparable to those of the straight WC-Co grades.

The pH value is one of the most important parameters when determining the corrosivity of a medium, but other factors also have a major influence, such as the temperature and the electric conductivity of the medium. The latter is dependent on the ion concentration, i.e. the amount of dissolved salts in the solution. Thus, one cannot define the corrosivity of a certain medium in a simple way and, accordingly, no general rules are valid in all situations. However, as a first indication of the corrosion resistance of cemented carbides, the Sandvik datasheet "Cemented carbide selection guide for corrosion resistance" shows different types of cemented carbides exposed to some common media.

For a particular choice of grade, we recommend that tests are carried out in the medium considered or, for orientation only, an analysis of the medium concerned.

.jpg)

Corrosion rate as a function of the pH value for different types of cemented carbides tested in buffered solutions. These tests include a final surface wear treatment by rumbling in order to obtain a true value of the depth of the corroded surface zone.

|

Gradient and comoound materials

|

The material properties required in the core of many products are often quite different from those needed in their surface zone or on the very surface of the finished part.

A stiff and rigid body might be needed from a mechanical point of view, but high wear and corrosion resistance might be equally important service requirements for the component. Materials which meet these different demands do not necessarily need to have the same composition and microstructure throughout the whole body.

Compound steel is one example of a material which has been used for a long time to combine cheap and strong bulk materials with highly alloyed and expensive corrosionresistant surface materials. Similar materials have also been developed for cutting tool applications where a thin coating offers suitable wear resistance and a cemented carbide the mechanical strength needed in heavy operations. For wear parts, the situation is often very similar'. In the case of a mandrel, the wear resistance of the surface is very important but at the same time toughness and mechanical strength are needed to support the surface zone. The wear' on mineral tools and highway engineering tools is often severe and requires high tool hardness, but a high tool toughness is also needed to withstand shock loads.

As a result of an extensive research and development programme, Sandvik Hard Materials has intro-duced two product concepts to offer solutions to such problems. Solutions which offer unique properties and which are not achieved with a single homogenous material.

The first group is based on the Sandvik DP-carbide, which is composed of a cemented carbide with different amounts of hard constituents in the surface and the core to achieve the optimum combination of hardness, wear resistance and toughness. The other group consists of a compound material - Sandvik Caslin Carbide. This material is a combination of two different materials. a stiff and wear-resistant cemented carbide, supported by tough cast iron which is less expensive and easier to machine.

.jpg)

Surface zone with a high volume of hard phase (WC) and a low volume of binder phase (Co) for increased wear resistance. Compressive stresses guarantee increased strength.Intermediate zone enriched with Co binder phase for high toughness.

Core with a Co binder phase content between that oI the two other zones.

DP Carbide

For conventional cemented carbides, wear resistance and toughness are related in such a manner that an improvement in one property results in a deterioration in the other.

company has developed an entirely new type of WC-Co cemented carbide in which wear resistance and toughness can be improved independently of each other. By means of a controlled redistribution of the cobalt binder phase, cemented carbide components can now be made which contain three distinct microstructural zones, each of which has different properties. These gradients, together with the differences in thermal expansion, redistribute the internal stresses. For example, it is possible to create a very hard and wear-resistant surface layer which is simultaneously pre-loaded with

. compressi ve stresses to prevent the initiation and propagation of cracks.

A carbide having such a distribution of properties-has high wear resistance at the surface combined with a tough core. These materials have therefore been given the designation DP - Dual Property. Their initial application area was in rock drilling. Other applications, such as tools for tube and wire drawing

and cold heading dies, have also confirmed improved performance.

The DP concept is covered by Sandvik patents.

SANCIC Cast-in Carbide

By utilising granules or tiles of cemented carbide as reinforcement of a cast iron surface, a new generation of composite materials has been developed. The high wear resistance of cemented carbide is combined with the strength and toughness of cast iron .

In the casting process a strong metallurgical bond is established between the carbide and the iron. Granules are mainly used in products exposed to high impact. Tiles are used in high erosion fields or to gain sharp edges and corners. Granules and tiles can, of course, be mixed in the same product. .

The granules account for about 50% of the volume in the composite zone and have an average size of 1-6 mm.

A typical SANCIC product has a wear resistance close to that of solid cemented carbide and 80-90 % of the strength of pure nodular cast iron. Toughness is maintained within the range expected from conventional engineering steels and as such considerably outperforms the high chromium and high nickel cast iron alloys.

SANCIC products have a wear resistance which is typically 3-15 times that of conventional solutions in steel, cast iron and designs with hardfacing or ceramics. SANCIC can be utilised in most component shapes and sizes.

.jpg)

SANCIC is produced in the form of composite or clad material. In the first case, cemented carbide granules are cast together with nodular iron. Alternatively, cemented carbide tiles are embedded in the exposed surface zone of the base material. The casting method used ill both cases provides a metallurgical bond between the cemented carbide and the base material.

Cemented carbide in comparison with other materials

The design and construction of components for demanding technical applications, frequently requires materials with unique combinations of properties. Finding the optimum solution is not an easy task and the engineer has to have a broad knowledge of many different groups of materials. Cemented carbides have a unique combination of properties and can be the optimum solution in many cases. To make your choice easier, the following tables are offered as a guideline, with the properties of WC-Co cemented carbides compared with those of some other materials. Note, for instance, the interesting combination of high compressive strength, rigidity, hardness and low thermal expansion as well as the high electrical and thermal conductivity offered by WC-Co cemented carbides.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)